An anemometer is a more advanced instrument used for measuring and monitoring wind speed. Unlike a Windex, which primarily indicates wind direction, an anemometer focuses on quantifying the speed or velocity of the wind.

There are various types of anemometers, but the most common ones include:

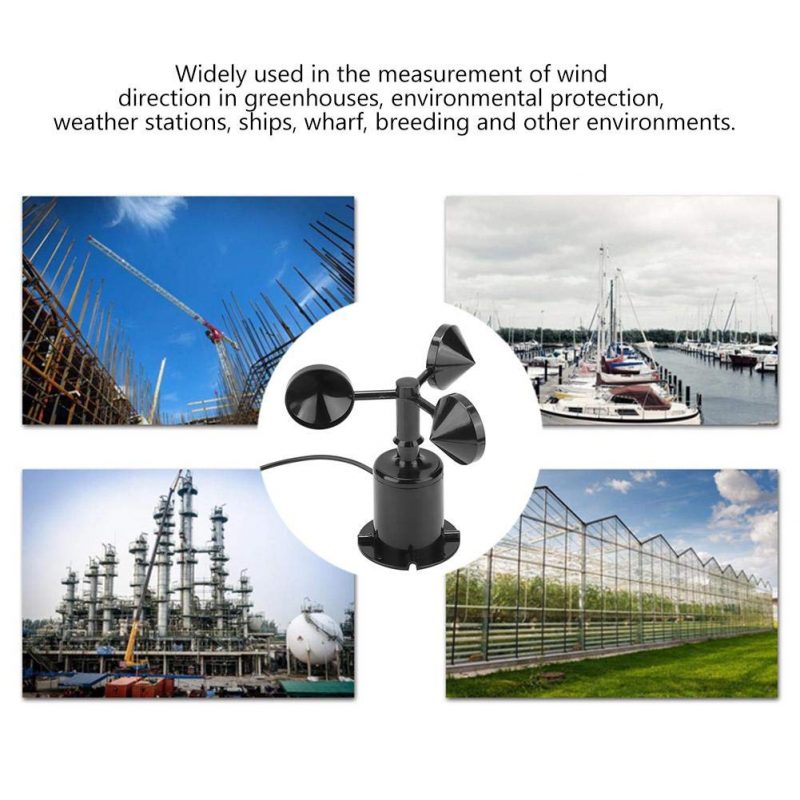

Cup Anemometers:

These consist of three or more small cups attached to a central axis. As the wind blows, the cups rotate. The speed of rotation is directly proportional to the wind speed. Here’s how they work:

These consist of three or more small cups attached to a central axis. As the wind blows, the cups rotate. The speed of rotation is directly proportional to the wind speed. Here’s how they work:

Cup Design: The cups are designed to be aerodynamic, meaning they’re shaped to minimize air resistance. This ensures that they capture the maximum amount of wind energy.

Rotation: As the wind blows, it hits the cups, causing them to spin. The faster the wind, the faster the cups rotate.

Counting Rotations: An anemometer is usually equipped with a mechanism that counts the number of rotations. This can be done mechanically or electronically.

Conversion to Wind Speed: The number of rotations is then converted into a wind speed measurement. This conversion is based on a known relationship between cup rotations and wind speed.

Cup anemometers are widely used in meteorology, climate research, and various industries that require accurate wind speed data. They are known for their reliability, especially in harsh weather conditions. Additionally, they are relatively simple devices, which makes them easy to maintain.

However, it’s worth noting that cup anemometers have limitations. They can sometimes underestimate wind speed, especially in turbulent or gusty conditions. For these situations, other types of anemometers, like sonic anemometers or wind vanes, may be used in conjunction with cup anemometers for more accurate measurements.

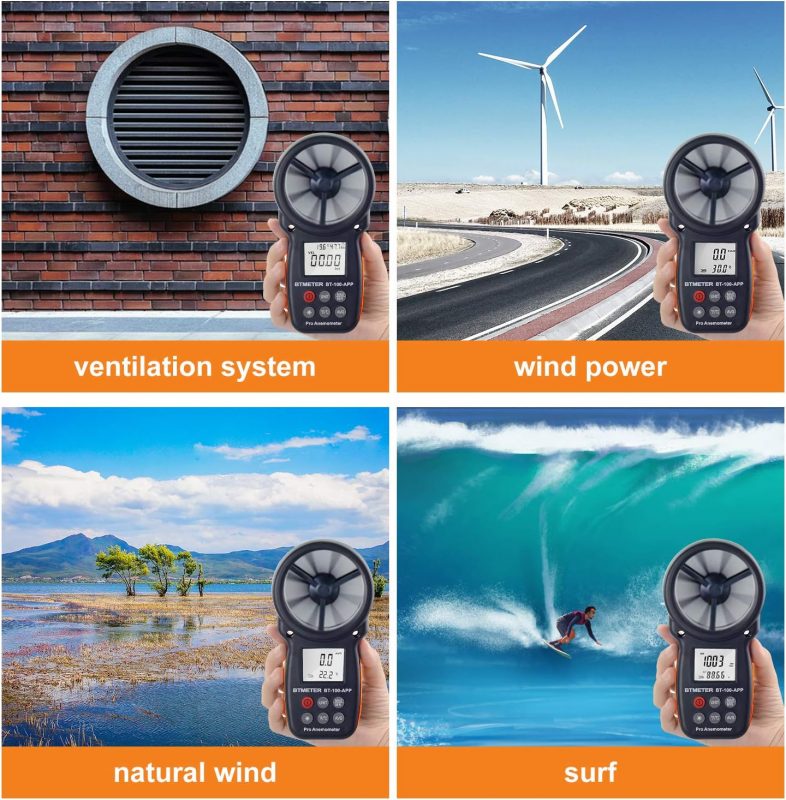

Vane Anemometers:

Vane anemometers, also known as wind vanes, are instruments used to measure wind direction and, in some cases, wind speed. These have a tail fin that points into the wind. The wind force on the tail causes the vane to rotate. This rotation is then translated into a measurement of wind speed. They work on a simple and intuitive principle:

Vane Design:

A vane anemometer consists of a vertical rod with a fin-like vane attached at one end. The vane is typically shaped like an arrow, with a larger surface area facing into the wind.

Alignment with Wind:

When placed in the wind, the vane naturally aligns itself with the direction of the wind. This is because the larger surface area of the vane faces into the wind, creating more air resistance on that side.

Direction Indication:

The vane is mounted on a pivot, allowing it to rotate freely. It is connected to a display or sensor that indicates the direction in which the vane is pointing. This provides a direct measurement of wind direction.

Some vane anemometers also incorporate additional features for measuring wind speed:

Cup Design:

In some models, cup anemometers (as described earlier) are integrated with the vane. This combination allows for simultaneous measurement of wind direction and speed.

Propeller Attachment:

Instead of cups, some vane anemometers have a small propeller attached at right angles to the vane. The propeller rotates as it encounters the wind, and the speed of rotation is directly related to wind speed.

Vane anemometers are commonly used in meteorology, aviation, environmental monitoring, and various industries where accurate wind data is important. They are especially valued for their ability to provide precise wind direction measurements, which is crucial for tasks like navigation, weather forecasting, and air quality monitoring.

However, it’s important to note that vane anemometers can be affected by turbulence and eddies near obstructions. In such cases, additional anemometers like cup anemometers or sonic anemometers may be used to complement the measurements.

Sonic Anemometers:

Sonic anemometers are sophisticated instruments used to measure wind speed and direction. They employ advanced technology and principles of acoustics to provide highly accurate and reliable wind data.These are more complex and use ultrasonic sound waves to measure wind speed. They are often used in research and meteorological applications. Here’s how they work:

Acoustic Pulses:

Sonic anemometers use pairs of transducers (ultrasonic sensors) to emit and receive high-frequency sound waves. These transducers are positioned in such a way that they form three orthogonal paths, allowing for measurements in three dimensions (x, y, and z axes).

Speed Measurement:

One pair of transducers is used to measure the speed of sound in the air. By analyzing the time it takes for the acoustic pulse to travel from one transducer to another, the anemometer can calculate the speed of sound. This value is essential for accurate wind speed measurements.

Wind Speed:

The remaining two pairs of transducers are used to measure the time it takes for acoustic pulses to travel in the upstream and downstream directions. By comparing these times, the anemometer can determine the speed of the wind along two perpendicular axes. The resultant vector gives the overall wind speed.

Wind Direction:

Sonic anemometers can also calculate wind direction based on the relative time it takes for the acoustic pulses to travel in different directions. This is accomplished by comparing the phase differences of the received signals.

Key features and advantages of sonic anemometers include:

– Non-Intrusive: They don’t have moving parts or physical obstructions, which means they don’t interfere with the airflow and are less prone to damage or wear.

– High Accuracy: Sonic anemometers offer very high accuracy in wind speed and direction measurements, especially in turbulent or complex flow conditions.

– Wide Operating Range: They can measure a broad range of wind speeds, from extremely calm conditions to severe storms.

– Minimal Maintenance: They require minimal maintenance compared to mechanical anemometers, which may need regular servicing or calibration.

Sonic anemometers find applications in meteorology, environmental monitoring, aviation, climate research, and various industries where precise wind data is crucial. They are often used in research, wind energy assessment, weather stations, and air quality monitoring. While they are more expensive than traditional anemometers, their accuracy and reliability make them invaluable in critical applications.

Hot-Wire Anemometers:

Hot-wire anemometers are precision instruments used to measure air velocity. They operate on the principle of convective heat transfer, and they’re particularly effective in low airspeed environments. These use a fine wire that is electrically heated. As the wind flows past the wire, it cools it down, and the change in electrical resistance is used to calculate wind speed. Here’s how they work:

Heating Element:

A fine wire (typically made of platinum or tungsten) is used as the sensing element. This wire is heated to a constant temperature using an electrical current. The wire’s resistance changes with temperature, allowing for a precise measurement.

Cooling Effect of Airflow:

When air flows over the heated wire, it carries away heat, causing the wire’s temperature to drop. The wire’s resistance changes in response to this temperature change.

Resistance Measurement:

The instrument continuously monitors the wire’s resistance, which is directly related to the airspeed. As the airspeed increases, the wire cools down more rapidly, leading to a corresponding change in resistance.

Signal Processing:

The change in resistance is converted into an electrical signal, which is then calibrated to provide an accurate measurement of air velocity. This signal is often displayed on a digital screen or transmitted to a data logger for further analysis.

Key features and advantages of hot-wire anemometers include:

– High Sensitivity: They are highly sensitive to even the slightest changes in airspeed, making them suitable for measuring low velocities.

– Quick Response Time: Hot-wire anemometers offer rapid response times, allowing them to capture transient airflow changes.

– Wide Range of Applications: They can be used in various environments, including clean air applications like HVAC systems and more turbulent settings like aerodynamic research.

– Non-Intrusive: They do not obstruct the airflow significantly, making them suitable for use in confined spaces and wind tunnels.

– Versatility: Some models can be equipped with multiple probes to measure airflow in different directions simultaneously.

Hot-wire anemometers are commonly used in aerodynamic research, HVAC system testing, environmental monitoring, and fluid dynamics experiments. They are highly accurate and offer excellent performance in low-velocity scenarios. However, they can be delicate and may require careful handling to maintain accuracy and longevity.

Anemometers are widely used in various fields, including meteorology, environmental monitoring, aviation, and maritime industries. They provide valuable data for weather forecasting, climate research, and optimizing operations in industries that are influenced by wind conditions. In sailing, anemometers can complement the information provided by a Windex, giving sailors a more comprehensive understanding of wind conditions.

Selecting the right anemometer involves considering several key factors:

1. Purpose: Determine the primary purpose of the anemometer. Are you using it for sailing, weather monitoring, or some other application? Different models are designed for specific uses.

2. Accuracy and Precision: Look for anemometers with high accuracy and precision in wind speed measurements. This ensures reliable data for making critical decisions.

3. Range: Consider the wind speed range you expect to encounter. Ensure the anemometer can measure both the lower and upper limits you anticipate.

4. Durability: If you’re using the anemometer in harsh environments or for outdoor activities like sailing, opt for a rugged, weather-resistant model to ensure it stands up to the elements.

5. Display and Data Output: Choose an anemometer with a clear and easy-to-read display. Some anemometers also offer data logging and output options for further analysis.

6. Ease of Use: The device should be user-friendly, with intuitive controls and straightforward operation.

7. Power Source: Consider the power requirements of the anemometer. Battery-powered options are more portable, while some models offer solar or wind-generated power.

8. Additional Features: Depending on your needs, you might want extra features like temperature measurement, wind chill calculation, or even a compass for wind direction.

9. Brand and Reviews: Research reputable brands and read reviews from other users to get an idea of the anemometer’s performance in real-world conditions.

10. Budget: Set a budget based on your requirements and stick to it. There are anemometers available at various price points, so you’re likely to find one that fits your needs.

Remember, the best anemometer for one person might not be the best for another, as it largely depends on your specific use case and requirements. Always prioritize the features that are most important for your intended application. Here are five highly-rated anemometers

Maintaining an anemometer is crucial for ensuring accurate and reliable wind speed measurements. Here are some key steps for anemometer maintenance:

1. Regular Inspection: Periodically check the anemometer for any signs of physical damage, corrosion, or wear and tear. Inspect the sensor, cups, and connections for any abnormalities.

2. Cleaning: Keep the anemometer clean from dirt, dust, bird droppings, and other debris. Use a soft brush, cloth, or a can of compressed air to gently clean the sensor and cups.

3. Calibration: Calibration ensures that the anemometer provides accurate measurements. Follow the manufacturer’s instructions for calibration. This might involve adjusting sensitivity settings or verifying readings against a known standard.

4. Lubrication: Some anemometers have moving parts, like ball bearings, that may require lubrication. Use a suitable lubricant as recommended by the manufacturer.

5. Secure Mounting: Ensure that the anemometer is securely mounted. Loose or wobbly installations can affect accuracy.

6. Check Connections: Inspect the cables and connections leading to the anemometer. Look for signs of fraying, corrosion, or loose connections. Repair or replace any damaged parts.

7. Seal Maintenance: If the anemometer has a weatherproof seal, inspect it for any signs of wear or deterioration. Replace it if needed to maintain the device’s protection against the elements.

8. Battery Replacement: If your anemometer is battery-powered, check and replace the batteries according to the manufacturer’s recommendations. Weak or expired batteries can lead to inaccurate readings.

9. Software Updates: If your anemometer is part of a larger weather monitoring system with associated software, ensure that the software is up-to-date. Updates often include improvements in data accuracy and reliability.

10. Record Keeping: Keep a maintenance log where you record dates of inspections, calibrations, and any repairs or replacements performed. This helps track the anemometer’s performance over time.

11. Professional Servicing: For more complex or specialized anemometers, consider having them serviced by a professional technician or the manufacturer at regular intervals.

Remember to always consult the manufacturer’s guidelines and recommendations for specific maintenance procedures for your particular model of anemometer. This will help ensure that your device continues to provide accurate and reliable wind speed measurements.